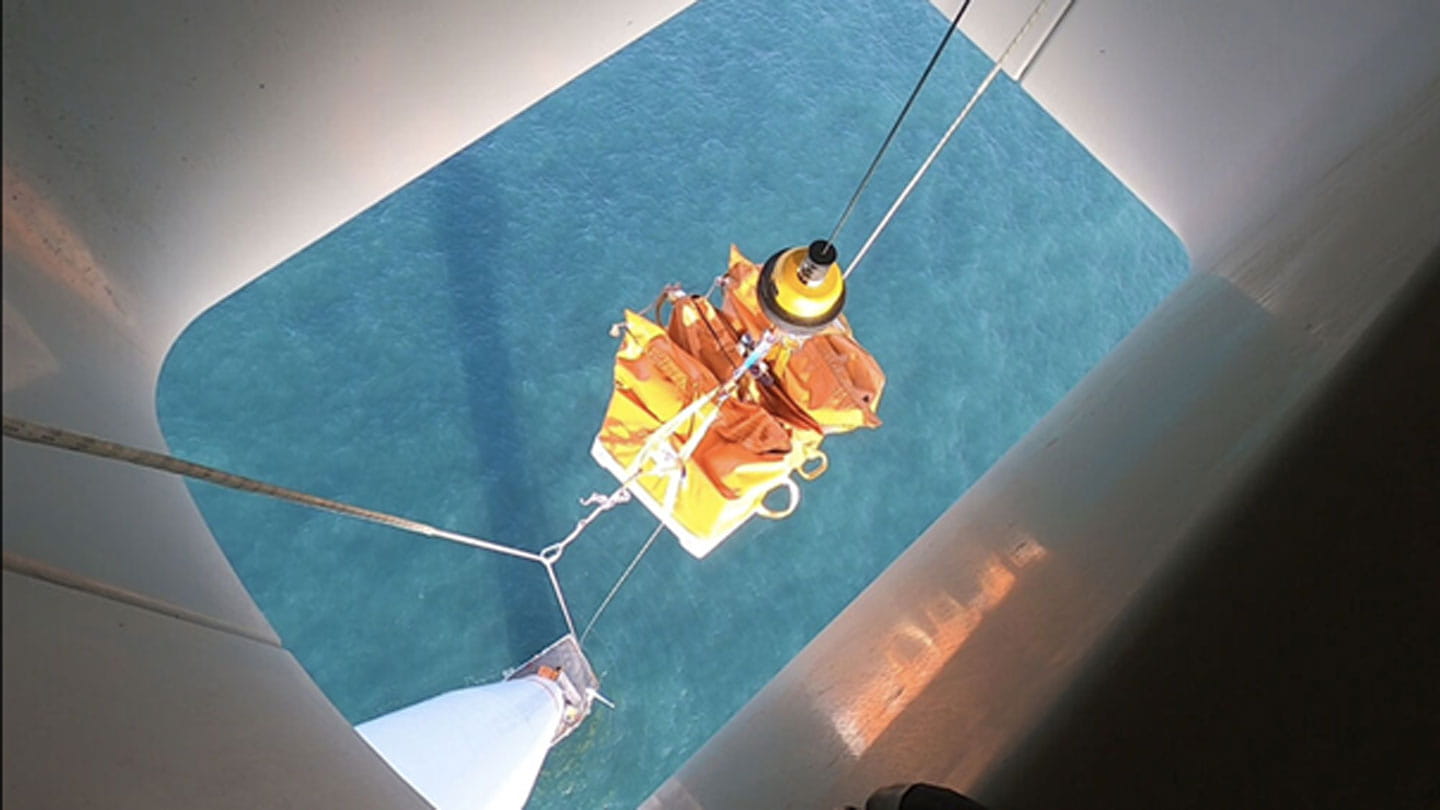

With crane assist, we can safely and securely transfer cargo containing spare parts and tools from a wind turbine platform to the nacelle without any risk of collision. This is especially important in windy conditions as crane assist enables wind turbine accessibility at wind speeds up to 18 metres per second, minimising wind turbine downtime and production loss. Crane assist needs minimal training and is being used across all of our G4, G6, and G8 wind turbines. For further ease of use, this product can be fitted to a wind turbine without the need for retrofitting or upgrades, and it travels with technicians as a stand-alone tool.

Want to learn more?

Reach out to us